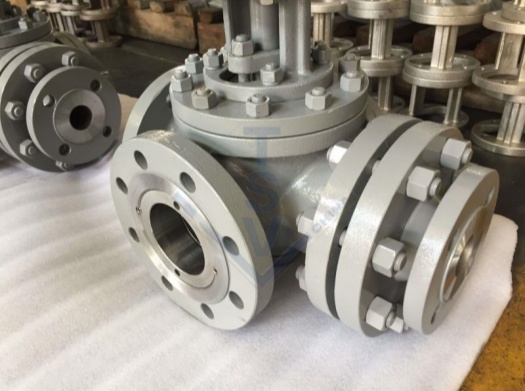

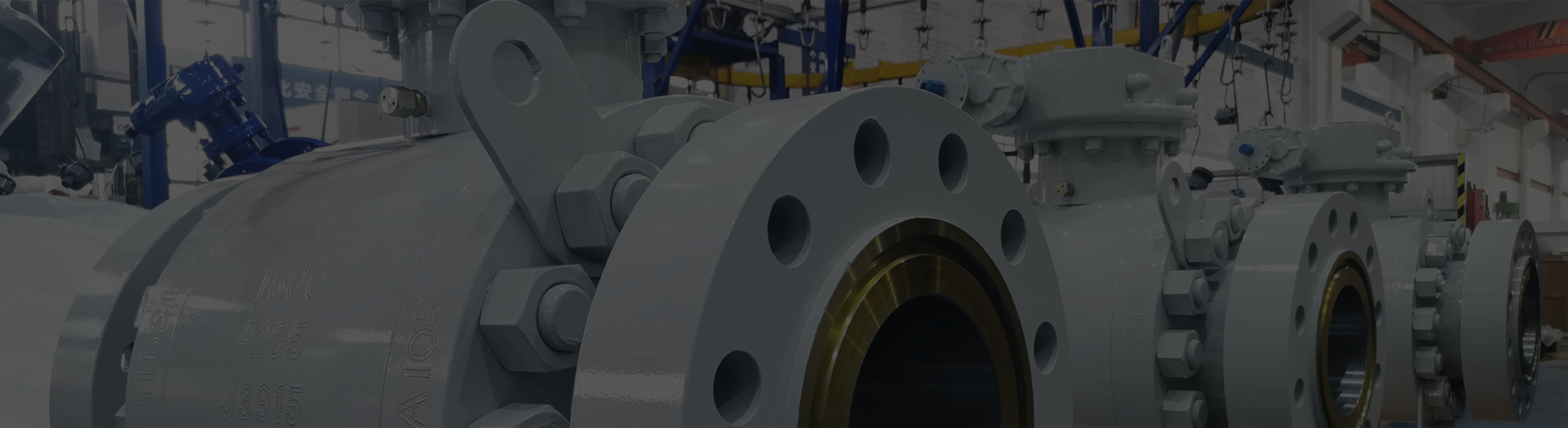

The 3-Way Ball Valve is a versatile and efficient industrial valve designed to control the flow of fluids in three different directions. It is widely used in applications where flow diversion, mixing, or distribution is required. The valve features a unique ball with an L-shaped or T-shaped bore, allowing it to direct flow in multiple directions. This makes it suitable for a variety of industries, including oil and gas, petrochemical, chemical processing, and water treatment.

Describes the design and product range:

Design basis:ASMEB16.34/ API608/DIN3357 、EN12516GB/T1224 GB/T12237

Face-to-face dimension:ASME B16.10/DIN3202/GB/T12221

Flanged ends:ASME B16.5/DIN2501/GB/T9113.1

Butt-welding ends:ASME B16.25/

Socket welding ends:ASME B16.11/

Wall thickness: ASME B16.34/ EN12516

Fireproof:API607 9ISO10479

Inspection and test:API6D/API598 /EN12266/GB/T13927

Product range:1/2″~10″、DN15~DN250

Materials of main parts:WCB、CF8、CF8M、WC6、WC

Seat materials:PTFE 、RTFE or metal hard seal

Design features:

-

Three-Way Flow Control: The 3-way ball valve can control flow in three different directions, making it ideal for applications requiring flow diversion, mixing, or distribution. The valve can be configured in L-port (90-degree flow change) or T-port (straight-through or 90-degree flow change) designs.

-

L-Port and T-Port Designs:

-

L-Port: Allows flow to be diverted between two ports at a 90-degree angle, making it suitable for flow diversion applications.

-

T-Port: Allows flow to be directed straight through or diverted between all three ports, making it suitable for mixing or distribution applications.

-

-

Floating or Trunnion-Mounted Ball: Depending on the application, the valve can feature a floating ball design (for low-to-moderate pressure applications) or a trunnion-mounted ball design (for high-pressure and large-diameter applications).

-

Bi-directional Sealing: The valve provides effective sealing in both directions, ensuring leak-proof operation regardless of the flow direction.

-

Durable Construction: The valve body and key components are made from high-quality materials such as stainless steel, carbon steel, or alloy steel, ensuring long service life and reliability in harsh environments.

-

Durable Sealing Materials: The seats and seals are made from high-performance materials such as PTFE, reinforced PTFE, or metal, depending on the application. These materials provide excellent sealing performance and long service life, even in corrosive or high-temperature environments.

-

Manual or Automated Operation: The valve can be operated manually using a handle or lever, or it can be automated using pneumatic, electric, or hydraulic actuators for remote and precise control.

-

Compact and Lightweight Design: The 3-way ball valve is generally compact and lightweight, making it easy to install and suitable for applications where space and weight are considerations.

Request a Quote

Request a Quote