Valve fitting includes flange, bolts, nuts, gaskets and so on.

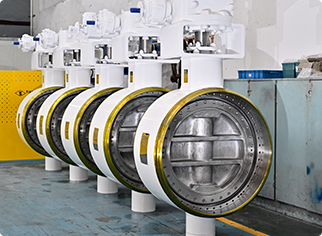

The company plans to purchase advanced production equipment such as CNC lathes, establish a fully intelligent high and low temperature butterfly valve production line, and introduce high and low temperature products

Upgrade the manufacturing level of laboratory testing equipment systems, high-precision measuring instruments, etc., thereby improving product quality and ensuring To ensure the stability of product quality and fundamentally promote the rapid development of enterprises.

Our products now have over 100 series and 2000 specifications, with an annual production capacity increasing from 150 tons to 60000 tons

Provide product qualification certificates, labels, quality assurance certificates, installation instructions, delivery lists, etc. in a timely and effective manner according to the contract requirements, and provide a 12-month product warranty period service and lifelong free consulting services.

The product installation and debugging company can arrange professional technical personnel to provide telephone guidance for installation. Ensure the preservation and filing of data information every time, and strictly maintain the confidentiality of user information.

A: Usually our Fittings are paired with valves, and our company mainly exports valves.

A: Rubber lined diaphragm valve is a special form of valve with shut-off function, which is composed of a steel valve disc and a diaphragm made of soft materials (rubber and fluoroplastic composite), and separates the inner cavity of the valve body from the inner cavity of the valve cover to achieve the purpose of cutting off the medium inside the pipe.

A: We have all kinds of materials to meet the requirement of the clients.

GET A QUOTE