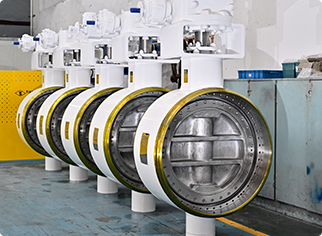

-Regular ball valves in a line are used for switching (on/off) the medium flow. Ball Valve is not a control valve in the sense that it cannot be maintained partially open during normal operations.

-It is open or closed by a simple 90° rotation of the command stem, which can be done manually or actuated depending the operating pressure and the valve bore.

Quick switch: Simple structure, easy operation, fast switching.

Corrosion resistance: Suitable for diverse media and conditions.

Wide applicability: Used in petroleum, chemical, gas industries.

Low fluid resistance: Minimal resistance in both standard and reduced diameter valves.

Includes ball, valve stem, and valve cover; available in two-body designs.

Thrust bearing reduces friction torque for smooth operation.

Anti-static function dissipates static during switching.

Applicable to various sizes and pressures, including high vacuum and high pressure.

Ideal for media with suspended solid particles.

The company plans to purchase advanced production equipment such as CNC lathes, establish a fully intelligent high and low temperature butterfly valve production line, and introduce high and low temperature products

Upgrade the manufacturing level of laboratory testing equipment systems, high-precision measuring instruments, etc., thereby improving product quality and ensuring To ensure the stability of product quality and fundamentally promote the rapid development of enterprises.

Our products now have over 100 series and 2000 specifications, with an annual production capacity increasing from 150 tons to 60000 tons

Provide product qualification certificates, labels, quality assurance certificates, installation instructions, delivery lists, etc. in a timely and effective manner according to the contract requirements, and provide a 12-month product warranty period service and lifelong free consulting services.

The product installation and debugging company can arrange professional technical personnel to provide telephone guidance for installation. Ensure the preservation and filing of data information every time, and strictly maintain the confidentiality of user information.

A: TSV’s design ideas of ball valves are:

- Ball valve is designed to API 608, valve has adequate strength according to ASME B16.34

Pressure temperature rating;

- Valve is designed with fire-safety structure certified in accordance with API 607;

- Valve contains no light metal (such as Mg) and all parts are electricity conductive and connected to prevent ignite resource;

-Valve is designed with hand wheel, or gear operator or electric actuator according to its

size and torque,and operation requirements.

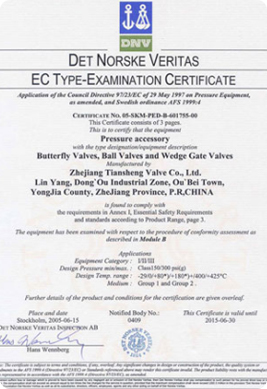

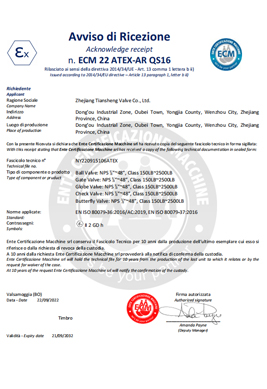

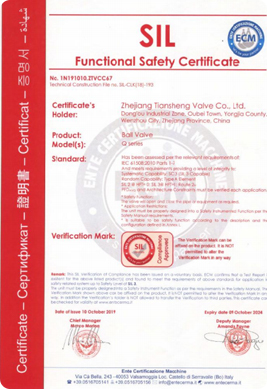

A:Yes! We have API 6D, ATEX, CE, ISO, and a fire certificate.

A:We have soft seat(PTFE, EPDM, etc) and hard seat(A105, A216 WCB, and stainless steel).

GET A QUOTE