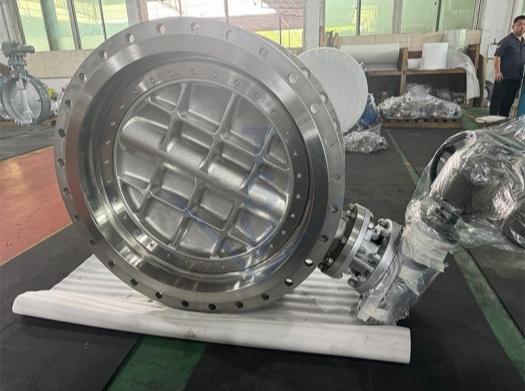

A TRIPLE OFFSET FLANGED BUTTERFLY VALVE is a high-performance valve designed for critical applications where tight sealing, durability, and reliability are essential. It is a type of butterfly valve that incorporates three distinct offsets in its design to achieve zero leakage and minimize wear, making it suitable for high-pressure, high-temperature, and corrosive environments.

Key Features:

-

Triple Offset Design:

-

First Offset: The shaft is positioned behind the seat to ensure a tight seal.

-

Second Offset: The shaft is offset from the centerline of the disc, allowing the disc to rotate without rubbing against the seat.

-

Third Offset: The sealing surface of the disc is conical, enabling a cam-like action that ensures a frictionless seal during operation.

-

-

Flanged Ends:

-

The valve features flanged ends for easy installation and secure connection to pipelines, complying with industry standards such as ASME, ANSI, or DIN.

-

-

Metal-to-Metal Sealing:

-

The valve uses a metal seat and disc, which provide excellent sealing performance and resistance to high temperatures and pressures. This eliminates the need for elastomeric seals, making it ideal for extreme conditions.

-

-

Bidirectional Sealing:

-

The triple offset design allows the valve to provide a bubble-tight seal in both flow directions, ensuring zero leakage.

-

-

Materials:

-

The valve body is typically made from robust materials such as carbon steel, stainless steel, or alloy steel, while the disc and seat are often made from corrosion-resistant materials like stainless steel or exotic alloys.

-

-

Operation:

-

The valve can be operated manually (via hand lever or gear operator) or automatically (via electric, pneumatic, or hydraulic actuators).

-

Advantages:

-

Zero Leakage: The triple offset design ensures a tight seal, even under high-pressure and high-temperature conditions.

-

Long Service Life: The frictionless operation reduces wear and tear, extending the valve's lifespan.

-

High Performance: Suitable for critical applications in industries such as oil and gas, petrochemical, power generation, and refining.

-

Low Maintenance: The robust design and metal-to-metal sealing reduce the need for frequent maintenance.

-

Versatility: Can handle a wide range of fluids, including steam, gases, and corrosive media.

Applications:

-

Oil and Gas: Used in pipelines, refineries, and offshore platforms.

-

Power Generation: Suitable for steam isolation and control in power plants.

-

Chemical and Petrochemical: Ideal for handling corrosive and high-temperature fluids.

-

Water Treatment: Used in high-pressure water systems.

Standards:

-

API 609: Standard for butterfly valves in the petroleum and natural gas industries.

-

ASME B16.34: Covers pressure-temperature ratings and materials for valves.

-

ISO 5752: Specifies face-to-face dimensions for butterfly valves.

-

ANSI B16.5: Standard for flanged connections.

Request a Quote

Request a Quote