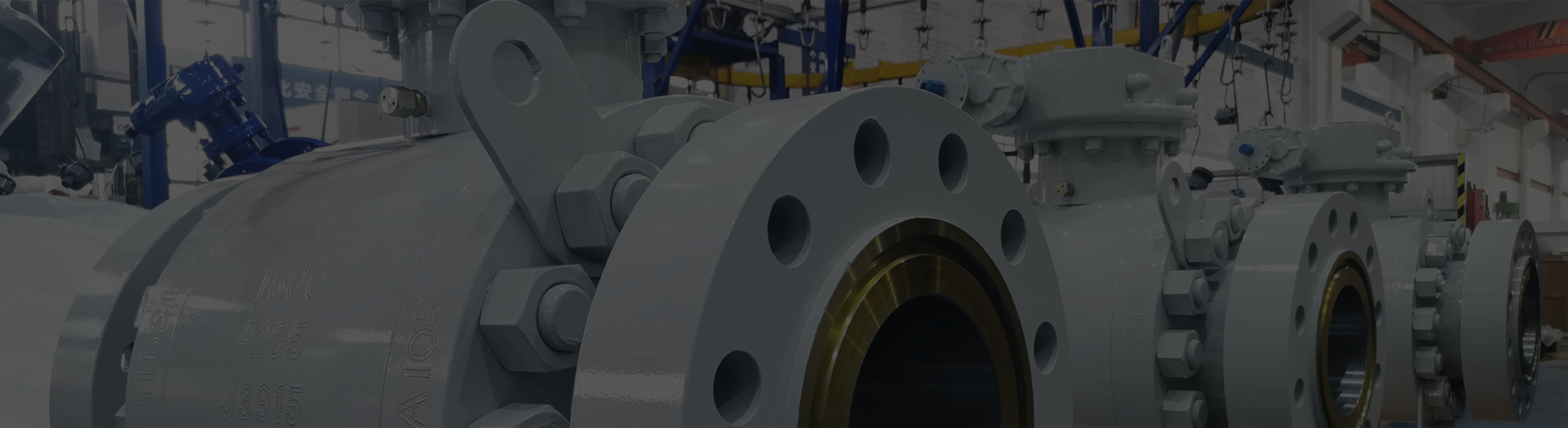

The Flange Gear Floating Ball Valve is a high-performance industrial valve designed for applications requiring reliable shut-off and control of fluid flow. This valve combines the strength and durability of a flanged connection with the efficiency of a gear-operated floating ball design. It is widely used in industries such as oil and gas, petrochemical, power generation, and water treatment, where manual operation and precise control are essential.

Key Specifications:

Materials: WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316 and F304L

Pressure: 150 to 1500lbs

Structure types: 2 or 3 pieces, reduced/full bore

Operated way: lever, handwheel and gear

Size: 1/2 to 10 inches

Standards:

Design and manufacture standards: API 608, API 6D and ASME B16.34

Face to face standards: API B16.10, API 6D and DIN 3202

End connection standards: ASME B16.5 and DIN 2543-2550

Test standards: API 6D and BS 6755

Key Features:

-

Flanged Ends: The valve is equipped with flanged ends, which provide a secure and leak-proof connection to the pipeline. Flanged connections are ideal for high-pressure applications and allow for easy installation and removal.

-

Gear Operation: The valve is operated using a gear mechanism, which provides mechanical advantage and reduces the effort required to open and close the valve. This makes it suitable for larger valves and applications where manual operation is preferred.

-

Floating Ball Design: The ball is not fixed in place and is free to move slightly within the valve body. When the valve is closed, the pressure of the fluid pushes the ball against the downstream seat, creating a tight seal. This design ensures reliable sealing and is particularly effective for low-to-moderate pressure applications.

-

Bi-directional Sealing: The valve provides effective sealing in both directions, ensuring leak-proof operation regardless of the flow direction.

-

Durable Construction: The valve body and key components are made from high-quality materials such as carbon steel, stainless steel, or alloy steel, ensuring long service life and reliability in harsh environments.

-

Durable Sealing Materials: The seats and seals are made from high-performance materials such as PTFE, reinforced PTFE, or metal, depending on the application. These materials provide excellent sealing performance and long service life, even in corrosive or high-temperature environments.

-

Fire-safe Design: Many flange gear floating ball valves are designed to be fire-safe, meaning they can maintain their integrity and prevent leakage even in the event of a fire.

-

Blowout-proof Stem: The stem is designed to prevent blowout, ensuring safe and reliable operation under high-pressure conditions.

Request a Quote

Request a Quote