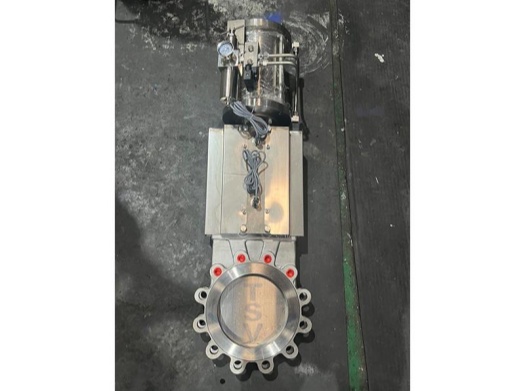

The pneumatic knife gate valve is a type of valve designed for handling fluids containing solids, slurries, or viscous media. It is widely used in industries where precise flow control and reliable shut-off are required. The valve is actuated by a pneumatic system, allowing for automated operation and integration into control systems.

Sizes: 2″ – 48″ or DN 50 – DN 1200

Pressure Rating: Class150 or PN6 – PN16

Materials of valve body: WCB, LCB, WC6, CF8, CF3, CF8M, CF3M, 4A, etc.

Features:

Wafer lug-type body

Beveled knife on metal or resilient seats

Self-cleaning mechanism

Bi-direction design

Non-rising stem

Pillar type yoke, more room for stem nut

Design & Manufacture:

MSS SP-61, ASME 16.34

Face to Face: MSS SP-81, ASME B16.10, EN 558

Connection End: ASME B16.5, EN 1092, JIS B2220

Test : MSS SP-81

Design Features:

-

Knife Gate Design: The valve features a sharp-edged gate that cuts through thick fluids, slurries, or solids, ensuring smooth operation and minimal clogging.

-

Pneumatic Actuator: The valve is equipped with a pneumatic actuator, which uses compressed air to open and close the gate. This allows for quick and precise control.

-

Sealing Mechanism: The valve uses elastomeric seals or resilient seats to ensure a tight shut-off, even in harsh conditions.

-

Compact Design: The knife gate valve has a slim, lightweight design, making it suitable for applications with limited space.

-

Bi-Directional Flow: Many models are designed to handle flow in both directions, providing flexibility in installation.

Request a Quote

Request a Quote