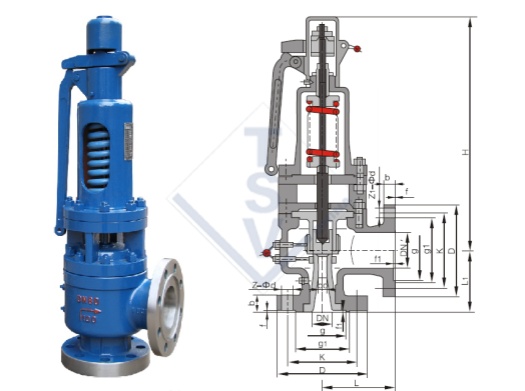

A High Temperature and Pressure Spring Loaded Full Lift Type Safety Valve is a critical safety device designed to protect high-pressure and high-temperature systems from overpressure conditions. It is engineered to operate reliably in extreme environments where both temperature and pressure are significantly elevated, such as in power plants, chemical processing, oil and gas industries, and steam systems.

Key features:

-

Full Lift Design: The valve disc lifts completely, providing maximum flow capacity for rapid pressure relief in high-pressure systems.

-

Spring-Loaded Mechanism: Ensures precise and reliable operation, with the spring calibrated to the system's set pressure.

-

High-Temperature Capability: Constructed from materials capable of withstanding extreme temperatures, ensuring durability and performance in harsh environments.

-

High-Pressure Resistance: Designed to handle systems with very high pressure, making it suitable for critical industrial applications.

-

Automatic Resealing: Once the pressure drops below the set point, the valve automatically closes, maintaining system integrity.

-

Robust Construction: Made from high-quality materials such as stainless steel or alloy steel to resist corrosion, erosion, and thermal stress.

-

Compliance with Standards: Typically complies with international standards such as ASME, API, or ISO, ensuring safety and reliability.

Applications:

-

Power Generation: Used in boilers, steam turbines, and other high-temperature and high-pressure systems.

-

Oil and Gas: Protects pipelines, reactors, and storage tanks from overpressure.

-

Chemical Processing: Safeguards reactors, distillation columns, and other equipment in high-temperature and high-pressure environments.

-

Industrial Steam Systems: Ensures safe operation of steam boilers and related equipment.

This type of safety valve is essential for maintaining the safety and efficiency of systems operating under extreme conditions, providing reliable overpressure protection and preventing catastrophic failures.

Request a Quote

Request a Quote