Raw material Inspection

Raw material Inspection

Visual Control

Dimension measure

Wall Thickness

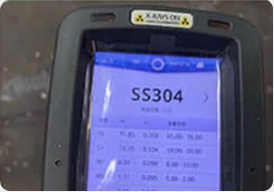

PMI

Mechanical Properties

Quality Control

Process Control

Dimension measure

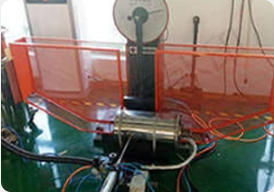

PT Test

MT Test

UT Test

RT Test

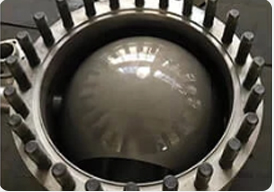

Assemb lingInspection

Process Control

Dimension measure

PT Test

MT Test

UT Test

RT Test

Final Inspection

Visual Control

Painting thickness

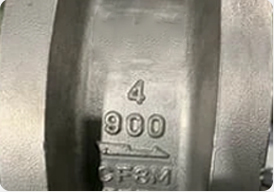

Identification

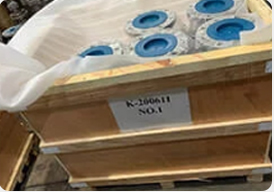

Packing

Fastening ball valve

Sea Worthy Packing