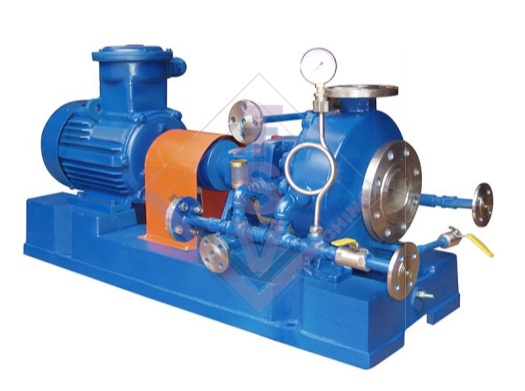

The IR Series Heat Preservation Pump is a specially engineered centrifugal pump designed for high-temperature fluid handling with integrated thermal management systems. These pumps maintain optimal fluid viscosity and prevent product solidification in processes requiring precise temperature control from 150°C to 450°C.

Technical Specification:

· Capacity: 8-460m³/h

· Head: 5-125m

· Speed: 1450-2900r/min

· Size: DN50-200mm

· Temperature: -50°C-250°C

Characteristic:

IR heat preservation pump's main flow part has hollow interlayer, and multi-cycle for transporting the steam, hot water, hot oil and soda pop. Heat preservation has a variety of ways with the heat preservation outside.

Core Technologies:

1. Advanced Thermal Management System

-

Triple-Layer Jacketing:

-

Inner heat transfer layer (316L stainless steel)

-

Middle insulation layer (ceramic fiber)

-

Outer protective cladding (304 stainless steel)

-

-

Steam/Oil Circulation Channels:

-

Standard steam heating (150-220°C)

-

Optional thermal oil system (up to 450°C)

-

Electric trace heating options available

-

2. High-Temperature Mechanical Design

-

Hot-Oxidation Resistant Materials:

-

Shaft: Incoloy 800H (standard), Hastelloy X (optional)

-

Bearings: High-temperature graphite lubricated

-

Seals: Gas-lubricated dry-running or double cartridge seals

-

-

Thermal Expansion Compensation:

-

Floating bearing design accommodates 15mm axial expansion

-

Flexible coupling with ±5° angular misalignment capacity

-

3. Smart Temperature Control

-

Integrated Sensors:

-

RTD temperature monitoring (4-20mA output)

-

Vibration analysis for bearing health

-

Heat medium flow control valves

-

-

Automation Interface:

-

MODBUS RTU/Profibus DP protocols

-

Predictive maintenance alerts

-

Request a Quote

Request a Quote