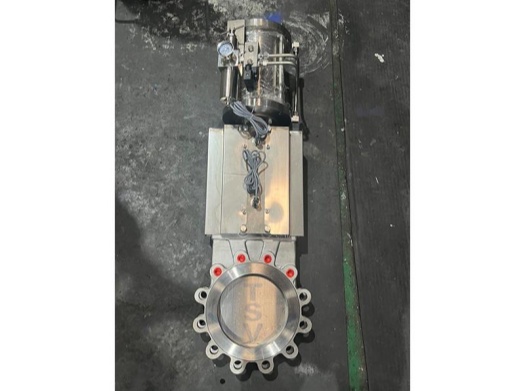

The ANSI Standard Bellow Seal Gate Valve is a high-performance valve designed to meet the rigorous requirements of the American National Standards Institute (ANSI). It is specifically engineered to provide zero leakage in critical applications involving hazardous, toxic, or high-temperature fluids. The valve features a metallic bellows seal that acts as a secondary barrier, ensuring complete isolation of the fluid from the environment and enhancing safety in demanding industrial processes.

Key Specifications:

- Main specifications:

- Size: 2 to 14-inch DN 50 to 350

- Pressure: 150 to 600lbs

- Design and manufacture: ANSI B16.34

- Face to face: ANSI B16.10

- Flanged ends: ANSI B16.5

- BW ends: ANSI B16.25

- Test and inspection: API 598, API 6D

- Main parts materials:

- Body-bonnet: cast steel A216WCB, alloy steel A217 WC6, WC9, stainless steel

- Sealing face: A182 F6, A182 F304, F316, monel

- Stem: A182 F6, A182 F304, F316, monel

- Full range of trim materials to match any services

Key Features:

-

Bellow Seal Design:

-

Metallic Bellows: A stainless steel or alloy bellows forms a hermetic seal around the valve stem, eliminating leakage paths and preventing fugitive emissions.

-

Double Sealing: Combines the primary seat seal with the bellows seal for redundant leak protection.

-

-

Material:

-

Body Material: Typically constructed from cast steel (WCB, WCC), stainless steel (CF8, CF8M), or exotic alloys for corrosion resistance.

-

Seat and Disc: Hardened stainless steel or surface-coated materials to ensure durability and tight sealing.

-

-

ANSI Compliance:

-

Designed and manufactured in accordance with ANSI standards, ensuring compatibility with ANSI-rated piping systems.

-

Compliant with ASME B16.34 for pressure-temperature ratings and API 602 for compact gate valves.

-

-

Operation:

-

Manual operation (handwheel or gear operator) or automated actuation (electric, pneumatic).

-

Smooth stem movement enabled by the bellows, reducing friction and wear.

-

-

Applications:

-

Ideal for handling hazardous chemicals, high-pressure steam, cryogenic fluids, and volatile hydrocarbons.

-

Request a Quote

Request a Quote