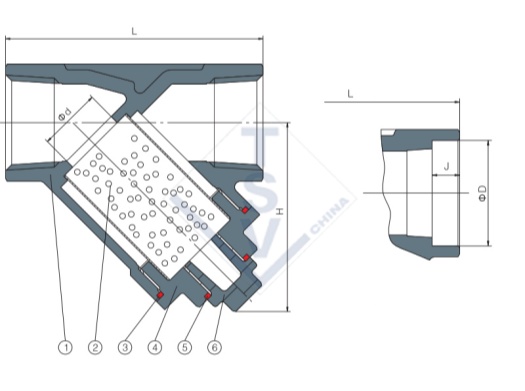

A Stainless Steel (SS) SW/FNPT/BSPT Y Strainer is a high-quality filtration device designed to remove solid particles and debris from fluids in piping systems. Constructed from stainless steel, it offers excellent corrosion resistance, durability, and suitability for high-pressure, high-temperature, and corrosive environments. The strainer features Socket Weld (SW), Female National Pipe Thread (FNPT), or British Standard Pipe Taper (BSPT) connections, making it versatile for various industrial applications.

Products Details:

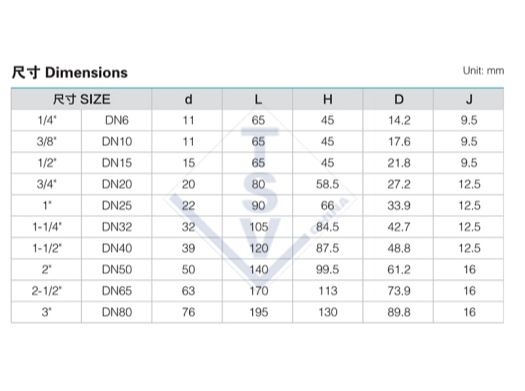

Size: 1/4"~3"(DN6~DN8)

Working Pressure: 800WOG(PN50)

Material: WCB, CF8, CF8M, CF3, CF3M

Working Temperture: -20℃~180℃

Investment Casting

Thread End: ASME B1.20.1(NPT); DIN 259/DIN 2999; BS21; ISO 288-1; ISO 7-1

Socket Werd End: ASME B16.11

Key Features:

-

Stainless Steel Construction:

-

Made from high-grade stainless steel (e.g., 304 or 316), providing superior corrosion resistance and durability.

-

Ideal for use in aggressive environments, such as chemical processing, marine applications, and food and beverage industries.

-

-

Y-Shaped Design:

-

Features a Y-shaped body that allows for efficient filtration with minimal pressure drop.

-

The design provides easy access to the filter screen for cleaning or replacement.

-

-

Connection Types:

-

Socket Weld (SW): Provides a strong, leak-proof connection for high-pressure systems.

-

Female National Pipe Thread (FNPT): Offers easy installation in threaded piping systems, commonly used in North America.

-

British Standard Pipe Taper (BSPT): Suitable for threaded connections in European and Asian markets.

-

-

Filtration Mechanism:

-

Utilizes a stainless steel mesh or perforated screen to capture debris, rust, and other solid particles from the fluid.

-

The screen is available in various mesh sizes to suit different filtration requirements.

-

-

Applications:

-

Commonly used in chemical processing, oil and gas, water treatment, food and beverage, and pharmaceutical industries.

-

Suitable for filtering liquids, gases, and steam in high-pressure, high-temperature, and corrosive environments.

-

-

Advantages:

-

Protects downstream equipment (e.g., pumps, valves, and meters) from damage caused by debris.

-

Reduces maintenance costs and downtime by preventing clogging and wear.

-

Durable and reliable in extreme operating conditions.

-

Easy to install, clean, and maintain.

-

Request a Quote

Request a Quote